-

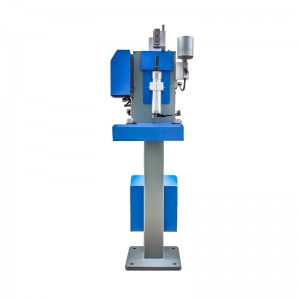

Mīkini Welding Laser Paʻa Paʻa Thor Compact

Nā hiʻohiʻona:

1. Loaʻa ka mīkini wiliwili me 1.5kW, 2kW a me 3kW laser diodes

2. Maikaʻi wiliwili wili me ka liʻiliʻi distortion, kūpono no 0.5-5mm mānoanoa wiliwili

3. ʻO nā mea hoʻohui koho no ka hoʻoheheʻe ʻana i ka laser autogenous, ka hoʻopiha ʻana i ka uwila laser, a me ka laser brazing

4. E hui pū me nā lopako ʻoihana e hui pū i ka hiki a me ka maʻalahi o nā mea paʻakikī a me nā mea nui.

5. E pili ana i nā ʻoihana o ka ikehu hoʻomau, ka hana kaʻa, ka hoʻoili metala, ka uila, ke kaʻaahi etc.

6. He liʻiliʻi ka wahi i hoʻopili ʻia i ka wela i ka wā wili, ʻaʻole ia e hoʻopuka i ka deformation, ʻeleʻele, a i ʻole nā ʻili ma luna o ka mea hana, a lawa ka hohonu o ka welding, paʻa ka hoʻoheheʻe ʻana, a nui ka hoʻoheheʻe ʻana. E maʻemaʻe a maʻemaʻe nā hopena kuʻi me ka ʻole o ka deformation a me ke kaumaha.

7. Hoʻohana ka huahana i kahi ʻōnaehana mana autonomous, optics paepae kiʻekiʻe, nā laka palekana lehulehu, nā mea hoʻoluʻu wai, a me kahi hoʻolālā ergonomic. Hoʻomaikaʻi nui kēia mau hiʻohiʻona i nā hopena welding, hoʻonui i ka palekana a me ka paʻa o nā mea hana, hoʻomaikaʻi i ka hōʻoluʻolu o ka mea hoʻohana, hoʻemi i ka luhi hana, a hoʻonui i nā hola hana.

Ua hoʻohana nui ʻia nā mea hana wili laser lima i nā noi wili o ke kila kila, aluminika, keleawe a me nā metala ʻē aʻe. No ka noi ʻana ma ka valve triangle, sensors, machinery, steel containers, metal pipe fittings and other sheet welding field, the laser welding method is a revolutionary way of work.

-

KELEI Copana Lopako Welding System

ʻO ka ʻōnaehana Copana ʻo KELEI ka hopena wiliwili robotic hou loa e hōʻike ana:

1. ʻenehana ʻokiʻoki

2. Ke kūlana laser kiʻekiʻe

3. Efficient uila-optic huli ana

4. Unique wili palapala noi

5. Mea hoʻohana aloha hana

6. Hoʻopili maʻalahi

7. Hiki ke hoʻololi ʻia ke ʻano kikoo laser

-

KELEI Thor Mekini Welding Laser Lima

Nā hiʻohiʻona:

1. Loaʻa ka mīkini wiliwili me 1.5kW, 2kW a me 3kW laser diodes

2. Maikaʻi wiliwili wili me ka liʻiliʻi distortion, kūpono no 0.5-5mm mānoanoa wiliwili

3. ʻO nā mea hoʻohui koho no ka hoʻoheheʻe ʻana i ka laser autogenous, ka hoʻopiha ʻana i ka uwila laser, a me ka laser brazing

4. E hui pū me nā lopako ʻoihana e hui pū i ka hiki a me ka maʻalahi o nā mea paʻakikī a me nā mea nui.

5. E pili ana i nā ʻoihana o ka ikehu hoʻomau, ka hana kaʻa, ka hoʻoili metala, ka uila, ke kaʻaahi etc.

6. He liʻiliʻi ka wahi i hoʻopili ʻia i ka wela i ka wā wili, ʻaʻole ia e hoʻopuka i ka deformation, ʻeleʻele, a i ʻole nā ʻili ma luna o ka mea hana, a lawa ka hohonu o ka welding, paʻa ka hoʻoheheʻe ʻana, a nui ka hoʻoheheʻe ʻana. E maʻemaʻe a maʻemaʻe nā hopena kuʻi me ka ʻole o ka deformation a me ke kaumaha.

7. Hoʻohana ka huahana i kahi ʻōnaehana mana autonomous, optics paepae kiʻekiʻe, nā laka palekana lehulehu, nā mea hoʻoluʻu wai, a me kahi hoʻolālā ergonomic. Hoʻomaikaʻi nui kēia mau hiʻohiʻona i nā hopena welding, hoʻonui i ka palekana a me ka paʻa o nā mea hana, hoʻomaikaʻi i ka hōʻoluʻolu o ka mea hoʻohana, hoʻemi i ka luhi hana, a hoʻonui i nā hola hana.

Ua hoʻohana nui ʻia nā mea hana wili laser lima i nā noi wili o ke kila kila, aluminika, keleawe a me nā metala ʻē aʻe. No ka noi ʻana ma ka valve triangle, sensors, machinery, steel containers, metal pipe fittings and other sheet welding field, the laser welding method is a revolutionary way of work.

-

KELEI Paʻa Paʻa Laser Welding Torch

Hiʻona:

1. KELEI kūʻokoʻa R&D huahana i hāʻawi 14 patents

2. Ma luna o 40% uila-optical hoʻololi wikiwiki

3. Nā noi ma nā ʻano mea like ʻole

4. Adjustable kuʻihao laula i kūpono no nā mea hoʻohana

5. Hoʻohālikelike me ka fiber 10-mika hiki ke kōkua i ka wiliwili lōʻihi

6. Hiki i nā helu o nā ʻano hana ke hoʻololi i kēlā me kēia kihi a paʻakikī

7. Nā loka pale lehulehu no ka palekana hana

-

Mea Hoʻohui Hoʻohui: KLPZ-O2 Nozzle

Nozzle i koho ʻia no KELEI Thor mīkini wiliwili lima lima lima

-

Mea Hoʻohui Hoʻohui: KLPZ-Y2 Nozzle

Nozzle i koho ʻia no KELEI Thor mīkini wiliwili lima lima lima

Welding Nozzle no ka wiliwili lima lima

Copper Premium/ Heat and slag resistance/ Nā koho piha o nā nuiHoʻokō Nui a Paʻa

ʻO ka mīkini maikaʻi / ka wela a me ka pale pale

ʻO ke kiʻekiʻe paʻakikī, ke kūpaʻa wela kiʻekiʻe a me ka conductivity kiʻekiʻe

Hoʻopili ʻia ka ʻili e hōʻemi i ka hoʻopili ʻana o ka slag lele, Hoʻopau maʻemaʻe e hōʻoia i ka paʻa o ka mana puka.

-

KELEI Robot-hoohana Laser Welding Torch

Hōʻike huahana:

Kūleʻa ʻo KELEI Laser i nā holomua i nā ʻenehana koʻikoʻi i hoʻomohala ʻia mai kā mākou ʻoihana alakaʻi mua. Ua hana ʻia nā makahiki o ka noiʻi koʻikoʻi i kā mākou Copana Robotic Welding system. Me nā ʻike mai kā mākou ʻoihana waiwai waiwai, ʻike ʻoihana, R&D a me nā mana hana, kā mākou i ka hoʻolaha ʻana i ka automation a me nā lako hana kiʻekiʻe kiʻekiʻe naʻauao, e kōkua i kā mākou mea kūʻai aku e hoʻokō i nā mea hou aʻe a emi ke kumukūʻai.

Hoʻokumu ʻia ka laser e ka laser a hoʻouna ʻia e ke ala optical waho. Ma hope o ka nānā ʻia ʻana e ke aniani hoʻohālikelike i ka hui kuʻi, hana ia i ka weld ma waena o nā mea e hana ʻia. Me ke kōkua o ke kinoea pale (e pale i nā mea mai ka oxidized), hoʻoheheʻe ʻia nā mea e hana i kahi wai hoʻoheheʻe kikoʻī, i mea e hoʻokō ai i ke kumu o ka welding.

-

KELEI Robotic Laser Cutting Head

Lawe kēia huahana i ka pono o ka maʻalahi a me ka neʻe wikiwiki o nā robots ʻoihana a me nā pāʻani me nā mea hahai a me nā mea hoʻoili optical. Hoʻohana ka huahana i ka ʻenehana laser fiber no ka hoʻomohala ʻana i nā ʻāpana kaʻina hana like ʻole no nā mānoanoa pā ʻokoʻa i ka wā e hana ana i ka ʻoki ʻana i ka pā multi-directional e hoʻokō i nā pono hana. I mea e hōʻoiaʻiʻo ai i kahi hoʻonohonoho maʻalahi a me ka ʻike mea hoʻohana, hāʻawi pū kā mākou hui i nā lawelawe debugging pūnaewele / offline e hoʻonā i kou hopohopo i ka wā e hoʻohana ai i ka nui loa.

-

ʻOki ʻokiʻoki robotic

1. E hoʻomalu me ka maʻalahi, mahalo i ke kūlana kiʻekiʻe o ka naʻauao pūnaewele

2. Hiki ke hoʻololi kiʻekiʻe a me ka maʻalahi i nā mea hana

3. Nā hualoaʻa oki kūlike a me ka maikaʻi o ka hoʻopuka

4. ʻO ka wikiwiki kiʻekiʻe, ka pololei, a me ka hilinaʻi

-

KELEI Hoomaemae Ulama

Hiʻona:

1. Hāʻawi pololei a hoʻomaʻemaʻe pono no ka hapa nui o nā welders robotic

2. ʻOki uwea nui ma lalo o nā kaiapuni hana koʻikoʻi

3. Hiki i ka wai anti-splash ke hoʻohaʻahaʻa i ka hopena o ka wiliwili ʻana a hoʻemi i ka pono o ka mālama

4. E ho'ēmi i ka wiliwili slag e pōmaikaʻi ai i ka hoʻohaʻahaʻa ʻana i ka pono mālama a hoʻolōʻihi i ka wā mālama

5. Nā hiʻohiʻona kūlana a me ka ʻoki uea kahi e hiki ai i ka mea ʻoki uea ke hana pololei a me ka hala ʻole

6. E hōʻoia i ke kūlana maikaʻi loa o ka lama ma o ka hoʻonui ʻia ʻana a me ka flash-over.

7. Hiki i nā mea kānana i kohoʻia ke kānana pono i kaʻaila, ka wai a me nā haumia i loko o ke kaapuni kinoea, kahi e hoʻonui ai i ke ola lawelawe o nā mea hana holoʻokoʻa.

8. ʻO ka hoʻohana ʻana i nā reamers kūikawā a me nā ʻoki ʻoki uea he paʻakikī kiʻekiʻe, a me ka paʻakikī ikaika, me nā ʻenehana o ka hoʻopaʻa ʻana i ka ʻaila hinu a me ka ʻoki uea maʻalahi, e hoʻomaikaʻi maikaʻi i ka lōʻihi a me ka maikaʻi shearing o nā mea hana.

-

KELEI Box Weld Station

Hiʻona:

1. ʻO ke kuʻi 'akomi i hoʻokahi ʻanuʻu me ka liʻiliʻi o ka distortion a me ka hoʻoponopono hope, kūpono me 0.5-5mm mānoanoa

2. Hiki i nā ʻāpana hoʻonohonoho mua ke hoʻopau koke i ka wili pahu a hiki i 800mm ākea

3. He kūpono no ka hana nui ʻana i nā huahana maʻamau

4. E pili ana i nā ʻoihana o ka ikehu hoʻomau, ka hana ʻana o ka metala, ka uila, ke kaʻaahi etc

5. Nā koho hoʻopuka laser like ʻole a hiki i 2kW

-

KELEI Aeolus Hoomaemae Lima Lima

Hiʻona:

1. Loaʻa ka mīkini hoʻomaʻemaʻe me 1kW, 1.5kW a me 2kW laser diodes

2. me nā poʻo hoʻomaʻemaʻe KELEI, ʻoi aku ka maikaʻi o ka hoʻomaʻemaʻe ʻana i ka 5-10x ma mua o nā huahana congeneric

3. Kūpono maikaʻi no ka hana ʻana i nā huahana nui a me ka nui

4. E pili ana i nā ʻoihana o ka ikehu hoʻomau, ka hana kaʻa, ka hana metala, ka uila, ke kaʻaahi etc.

5. ʻO ka pale ʻana i nā pae he nui + ke keʻena pale corrosion, ka hoʻolālā ʻana o ka ventila kū hoʻokahi, a me ka hoʻopau wela maikaʻi e hoʻonui i ka manawa hana o kā mākou huahana.

6. Hāʻawi ka ʻenehana hoʻomaʻemaʻe hoʻomaʻemaʻe pulse pulse i ka hoʻomaʻemaʻe ʻole e hoʻopōʻino i ka substrate. E hoʻomaʻemaʻe maikaʻi i ka pena ʻili, ka aila, ka ʻōpala, ke kiʻi ʻoniʻoni a me nā mea haumia ʻē aʻe ma luna o ka mea.